Metal Oxide Varistors for Surge Protection

How Our Metal Oxide Varistors Are Made

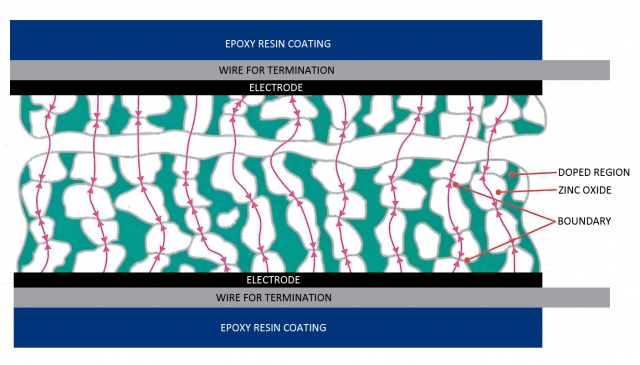

Our MOVs are manufactured from a blend of zinc oxide (ZnO) and other metal oxides. These materials are then pressed and sintered at extreme high temperatures to produce a polycrystalline structure with highly resitive boundaries between the highly conductive ZnO grains. The response voltage of each ZnO grain is approximately 4V, so the varistor voltage is achieved by connecting the grains in series to create a current path.

Electrodes are formed by the deposition of silver to a selected pattern. Some terminations are in the form of tinned copper wires which are soldered to the electrodes. The device is then coated in a tough epoxy resin which is moisture and flame resistant.

The electrical perfomance of the MOV is essentially controlled by its physical dimensions:

Current capability by cross-sectional area

Voltage by the varistor thickness

Energy rating by volume

Continuous development ensures improvemnets in the protection level, energy rating, current capability and life.

How The Metal Oxide Varistors (MOVs) Work

The MOV is essentially a back-to-back symmetrical doide with a characteristic similar to that of a Zener diode, A Zener diode is a silicon semiconductor device that permits current to flow in either a forward or reverse direction. The diode consists of a special, heavily doped p-n junction, designed to conduct in the reverse direction when a certain specified voltage is reached. A typical voltage – current characteristic (linear scale) is shown below.

The sharp breakdown characteristic enables the varistor to provide excellent transient suppression performance. In the presence of a voltage transient the impedance of the varistor changes by many orders of magnitude, from a virtual open circuit, where only a few microamps will pass at the maximum operating voltage, to a highly conductive path. This results in the transient being clamped to a safe level and the potentially destructive energy being absorbed in the mass of the varistor, thereby providing protection to vulnerable components. The MOV is capable of responding to the over-voltage within a few nanoseconds.

The Surge Solution

Surge Protection (Over-Voltage Protection) increases the reliability of your electrical equipment that it is being used on, thereby it reduces repair costs and costly out-of-service conditions. These transients can cause a breakdown or malfunction of semiconductors and insulations if not suppress to a safe level.

PD Devices Ltd Metal Oxide Varistors give an all-round standard of protection that other methods cannot claim. There are many ways to supress transients - the traditional CR Circuit - Spark Gaps - Diodes - Crowbars - Silicon Carbide Varistors etc, but none can combine the cumulative advantages of MOVs.

The Advantages of MOVs:

Low Clamping Voltage

Fast Response - Nanoseconds

High Energy Withstand

High Non-Linear Index

Low Leakage (DRAIN) Current (µA)

High Current Withstand

Suitable for AC and DC Circuits

Bipolar Operation

Wide Range of Operating Voltages

Small Size

Low Cost

Customised Solutions